Eco-friendly cards

At Precision Card Services, we take pride in our advanced digital and lithographic production facilities. Equipped with state-of-the-art card production and finishing equipment that allows us to add magnetic stripes, barcodes, and signature panels, as well as enhanced finishes such as metallic and special inks, matt/gloss lamination, spot UV as well as foil print and edging. We can produce cards using a variety of eco-friendly materials which include fully recyclable PVC, eco-degradable PVC, made from 100% recycled PVC and paper-board ensuring a sustainable option for card production.

Litho print

Utilising the KBA GENIUS 52UV waterless sheet fed offset press with UV curing technology, complements our passion to ensure all materials and processes are as environmentally sound as possible, whilst guaranteeing exceptional printing performance every time. Minimal dot gain produces extremely fine detailed print (micro print), whilst the 5 colour units provide flexibility to print CMYK, Pantones and specialist ‘invisible’ UV security inks.

Digital

Our dedicated digital printing and production facility houses the very best equipment in the industry, with the HP Indigo 5900 at the heart of it all. The HP Indigo technology opens up the options for mass personalisation, thicker substrates, special inks and most importantly high-quality print with a quick turnaround.

Screen print

Our Svecia silk screen press with air tunnel and IR drying, UV drying and autopile is compatible with a huge choice of inks including metallic, glitter, fluorescent, signature panels, specialist surface finishes such as spot UV gloss on matt. Offering enhanced versatility, the Svecia silk screen press is also available with a range of different meshes, allowing the flow of ink to be regulated for fine detail.

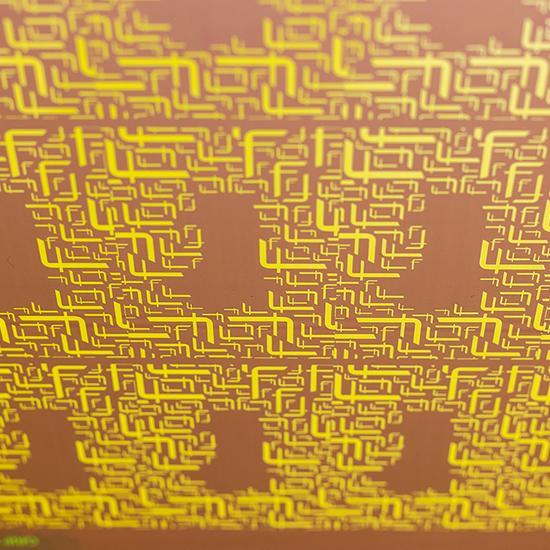

Hot foil printing & edge wrapping

Elevate your card designs with hot foil printing and edge wrapping. Offering a vast choice of foil types including metallic, matt, gloss and holographic, as well as a huge selection of colours available for hot printing means that the final result can be truly striking, and multiple blocks can be used to create patterns and craft layered designs. If you are looking to give your cards a premium feel then the patented card edging process adds a touch of class and perceived value to your cards.

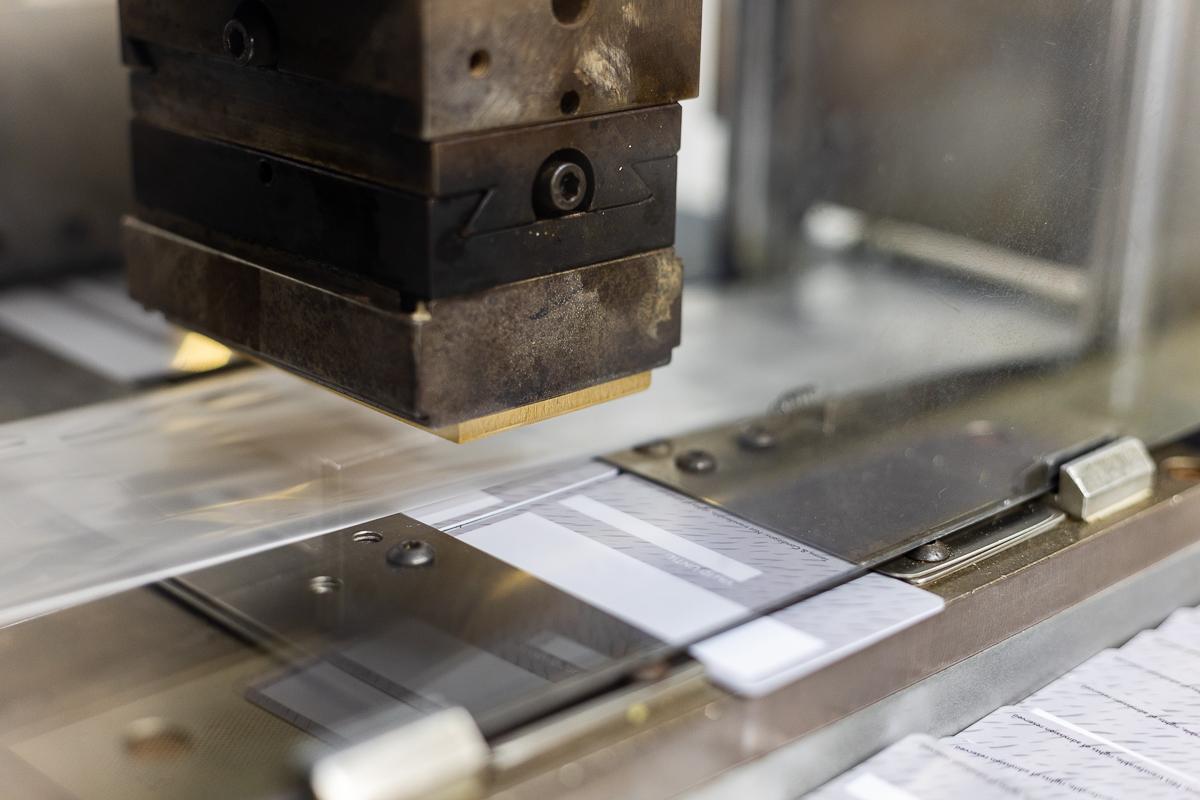

Finishing

Our Oasys finishing equipment, widely regarded as ‘industry-leading,’ is tailored for modern plastic card production. With an auto collator system, twin-stack laminator, automatic card punch and progression punch for key fobs, Oasys finishing technology ensures precision and efficiency for every card.

Artwork

The Precision Card Services® design studio covers all your artwork requirements. From original artwork creation using a client brief, to accepting press-ready files or dealing directly with your appointed agency, our highly experienced and dedicated artwork team is permanently on hand to provide expert advice for even the most complicated of jobs.

We use up-to-the minute equipment and operating systems supported by the latest version of the Adobe Creative Cloud suite including Photoshop, Illustrator and InDesign.

Let us know what you need

Looking for someone to help you with your card scheme then get in touch with one of our card specialists who can guide you through the card production process.